Production of REGENAPLEX® remedies

Production is carried out using the formulations developed by Günter C. Stahlkopf

Mother tinctures, tinctures and triturations are obtained from carefully sourced and certified suppliers. Homeopathic pharmaceuticals are manufactured in Switzerland according to the German Homeopathic Pharmacopoeia (HAB) using the following raw materials:

- Fresh plants or parts of fresh plants

- Dried plants or parts of dried plants

- Animal substances

- Mineral and inorganic raw material

ainsi que les agents et excipients prévus dans le HAB tels que : éthanol absolu, eau, glycerol, monohydrat de lactose.

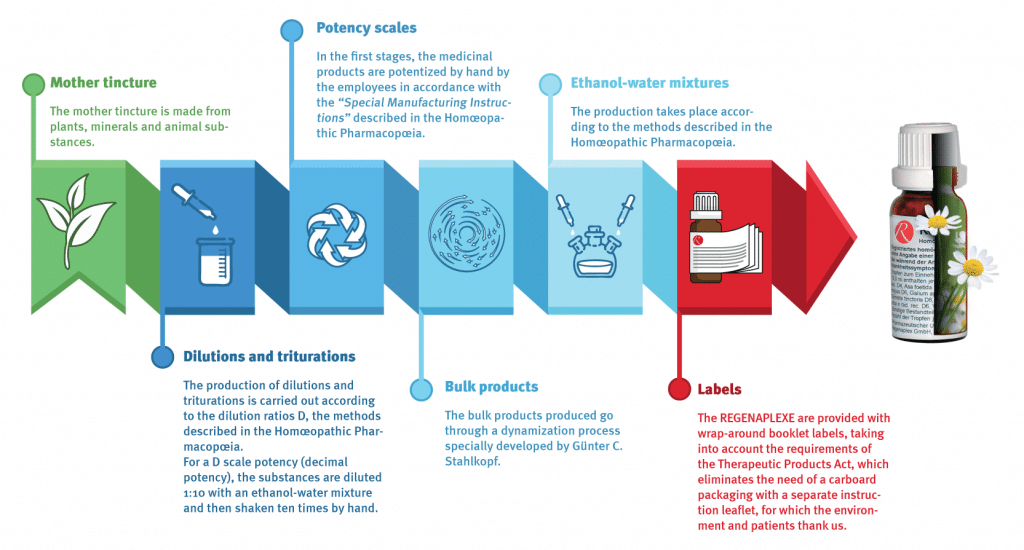

Production Steps

Dilutions and triturations

Production is carried out using dilution factor D as specified in the German Homeopathic Pharmacopoeia (HAB). For a D-Potentiation substances are diluted by a mixture of Ethanol-Water with the factor 1:10 and thereafter are shaken by hand 10 times.

Potentiation steps

The first steps of Potentiation are carried out manually as specified in the German Homeopathic Pharmacopoeia (HAB).

Bulk Production Batches

Produced bulk batches are treated by a special dynamisation-procedure developed by Günter C. Stahlkopf.

Purified water

Water is purified in three steps (demineralization, reverse osmosis, electro-deionisation); the purified water meets the specifications of the European Pharmacopoeia (Ph. Eur.).

Ethanol-alcohol water mixture

Production follows the methods specified in the Homeopathic Pharmacopoeia (HAB).

Labelling

Labelling conforms to specifications of the Swiss “Heilmittelgesetz (law on medical products)” . Labels with necessary information/instructions are attached directly to the bottles. For ecological reasons we do without outer packages and instruction leaflets.

Finished product

Bottles are filled, the medicine dropper inserted and bottles sealed on a filling line under sterilisation by a laminar-flow unit, followed by a 100 % control of the filling weight.

Quality Control

All raw materials received are thoroughly examined at the reception point and the end product is released upon approval. Testing is carried out according to the monographs of the German Homeopathic Pharmacopoeia (HAB), the European Pharmacopoeia (Ph. Eur.) and REGENA’s own specifications.

Stability testing and on-going stability testing of the starting material and of the finished products, in order to determine their durability, is carried out according to stability testing requirements, prescribed in REGENA AG durability specifications.

Quality Assurance

Product Quality Review (PQR)

To ensure product quality, all data concerning quality and production are assembled and analysed by means of a product quality review.

Maintenance

Equipment and facilities relevant for GMP are regularly calibrated, checked and serviced to ensure flawless functionality.